|

Posted on:

30 Aug 2013

|

According to the definition on Wikipedia “Serious Games are simulations of real-world events or processes designed for the purpose of solving a problem. Although serious games can be entertaining, their main purpose is to train or educate users, though it may have other purposes, such as marketing or advertisement. Serious game will sometimes deliberately sacrifice fun and entertainment in order to achieve a desired progress by the player. Serious games are not a game genre but a category of games with different purposes. This category includes some educational games and advergames, political games, or evangelical games. Serious games are primarily focused on an audience outside of primary or secondary education.”

In this month’s blog I would like to start a discussion about the usefulness of Serious Games within Chemical Engineering education and in the Process Industry.

In my opinion, one of the best ways for a new operator to learn the ins and outs of a plant he started working with, is to let him solve all kinds of real problems or situations that can occur during operation of the plant. Since a real plant normally runs very stable for long periods of time, it’s not very convenient to let an operator “play” with the real plant. A very good alternative would be to have a high-fidelity Operator Training Simulator to learn the process.

Operator Training Simulators can be seen as a first generation of Serious Games for chemical engineers and have already been around for decades. They started out as hardware-based solutions, but in the 1980s OTS applications became available for PCs. In the last decade a new innovation became available: A virtual reality component showing the outside operator view. This 3D world is dynamically linked to the process simulator.

With a 3D visualization a “Virtual Outside Operator” can actually open and close hand-operated valves, start and stop pumps, take field reading, see and hear equipment running, communicate with the control room, etc.. Instructors can mentor and manage training sessions, instead of being tied up in role playing the functions of an Outside Operator of previously provided “remote function” switches.

With a 3D visualization a “Virtual Outside Operator” can actually open and close hand-operated valves, start and stop pumps, take field reading, see and hear equipment running, communicate with the control room, etc.. Instructors can mentor and manage training sessions, instead of being tied up in role playing the functions of an Outside Operator of previously provided “remote function” switches.

At Mobatec we also have several years of experience of linking (real-time) dynamic process models to 3D visual plants. The 3D graphics are developed for us by the high-tech company ExplainMedia. Have a look at the short video if you are not sure what a 3D visualization of a plant is. I regularly show interactive examples of these very attractive and intuitive, dynamic 3D modules to lecturers at Chemical Engineering departments or technical staff of a chemical plant and initially they react very enthusiastically. However, when talking a bit longer to get a feel for if they would be interested in having such a 3D module from their own environment, they usually become more reluctant.

A feedback I often get when talking to these people is that adding a 3D world to the education or training modules would be a “nice to have”, but not a “must”. Which, of course, typically translates to “we would really like to have it, but it must be cheap!”. However, realizing a cheaper solution for industry, especially when looking at education, would also imply/ have as a side-effect that a lot Universities and Schools should be potentially interested in 3D modules. Otherwise it would not be worth the investment.

I am very interested in your view on this subject:

“Are interactive 3D visualizations of (parts of) chemical processes a valuable addition to a Chemical Engineering education and/ or learning tools of processing plants?”

I invite to post your comments, insights and/or suggestions in the comment box below.

To your success!

Mathieu.

———————————————–

In this month’s blog I would like to start a discussion about the usefulness of Serious Games within Chemical Engineering education and in the Process Industry.

In my opinion, one of the best ways for a new operator to learn the ins and outs of a plant he started working with, is to let him solve all kinds of real problems or situations that can occur during operation of the plant. Since a real plant normally runs very stable for long periods of time, it’s not very convenient to let an operator “play” with the real plant. A very good alternative would be to have a high-fidelity Operator Training Simulator to learn the process.

Operator Training Simulators can be seen as a first generation of Serious Games for chemical engineers and have already been around for decades. They started out as hardware-based solutions, but in the 1980s OTS applications became available for PCs. In the last decade a new innovation became available: A virtual reality component showing the outside operator view. This 3D world is dynamically linked to the process simulator.

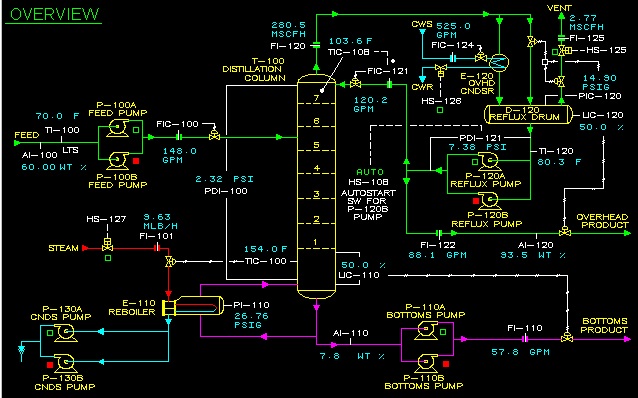

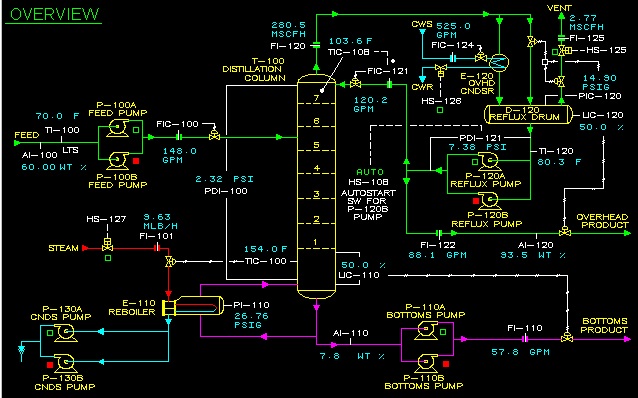

Screenshot of an OTS screen of more than 20 years ago..

At Mobatec we also have several years of experience of linking (real-time) dynamic process models to 3D visual plants. The 3D graphics are developed for us by the high-tech company ExplainMedia. Have a look at the short video if you are not sure what a 3D visualization of a plant is. I regularly show interactive examples of these very attractive and intuitive, dynamic 3D modules to lecturers at Chemical Engineering departments or technical staff of a chemical plant and initially they react very enthusiastically. However, when talking a bit longer to get a feel for if they would be interested in having such a 3D module from their own environment, they usually become more reluctant.

A feedback I often get when talking to these people is that adding a 3D world to the education or training modules would be a “nice to have”, but not a “must”. Which, of course, typically translates to “we would really like to have it, but it must be cheap!”. However, realizing a cheaper solution for industry, especially when looking at education, would also imply/ have as a side-effect that a lot Universities and Schools should be potentially interested in 3D modules. Otherwise it would not be worth the investment.

I am very interested in your view on this subject:

“Are interactive 3D visualizations of (parts of) chemical processes a valuable addition to a Chemical Engineering education and/ or learning tools of processing plants?”

I invite to post your comments, insights and/or suggestions in the comment box below.

To your success!

Mathieu.

———————————————–

The possibility of seeing and interact with a plant with a much more rich environment than a process simulator is good for everyone since the teachers to the students themselves running practice experiments before screwing it up in the pilot plan. I remember me esterification practice for the production of ethyl acetate we almost suffer from severe vapor burns because someone didn’t checked a vapor valve was opened before disconnect it. This environments could help people to interiorize security procedures.

Yes, in my opinion interactive 3D visualization of chemical processes help students/mentors to understand the exact plant scenarios. Many a times students dont know what they are being taught. This way it will make them conceptualize a theme under consideration and draws attention towards the subject under consideration and hence could prove a valauable resource in laying foundation stone of innovation in them.

I think serious gaming could be an addition to an OTS, however it depends on the target audience. From my experience in the chemical industry, even the value of an OTS is often discussed by the MT and it’s one of the first items which is scrapped of the yearly project budget. With that said, I think one step further: serious gaming in industry is even harder to justify. It could probably be helpful in getting youth interested in the chemical engineering/operations/maintenance before they actually already work in this type of industry, mainly to get them interested in this field of technology. I think that on top of the beautiful and realistic graphics a real “fun” play element should be added to the simulation.