|

Posted on:

28 Apr 2013

|

Last week Mobatec was presenting Mobatec Modeller at the ECCE 2013 (9th European Congress of Chemical Engineering) in The Hague (in The Netherlands). It was a great experience to be at this congress for several days and we met a lot of interesting people.

Obviously, the goal of being there was to promote our modelling methodology and tool, since “it is Mobatecs goal to bring this easy to grasp modelling methodology to the world and to teach engineers that modelling can actually be quite easy and very valuable.”

A question I had to answer quite often during our days at the congress was: “I know about this other tool (e.g. Aspen, Hysys, gProms, Matlab, ChemCad, ProSim, etc.). How is your tool different from what I already know?”

I noticed that people (before speaking to us) really did not realise there even could be an alternative approach to modelling and they all were genuinely interested in learning what this new modelling approach could offer. Therefore, I decided to devote a blog to this topic.

As I mentioned in a previous blog post on maintainability of process models there are typically 2 ways of constructing process models nowadays:

The first and most used approach, the “Unit oriented” or “flow sheeting” approach, I would not refer to as modelling myself, since you are only connecting (sub)models, which were completely defined by other people. You are merely “simulating” in this case and hoping that the persons who developed the models did such a good job that you get the results you require for your specific setup, with your required accuracy and your specific goal. In the rare case that you can actually see all the equations (so not only a few ones in some, mostly incomplete documentation file) that are used to get to the simulation results, they are either inaccessible or the listing is very long and very difficult/complex. Don’t get me wrong here, by the way, these tools can be very powerful and useful. I am just referring to the lack of flexibility of these programs to be able to adapt (or even just understand) the actual equations of the used models.

In the other approach, The “Equation oriented” approach, the user has the “freedom” to program everything himself. This is very flexible, but typically also a very tedious job. Much (programming) experience and a lot of patience is required to get a model up and running. The listings usually get very long (and hard to maintain), which paradoxically actually makes the end result quite inflexible.

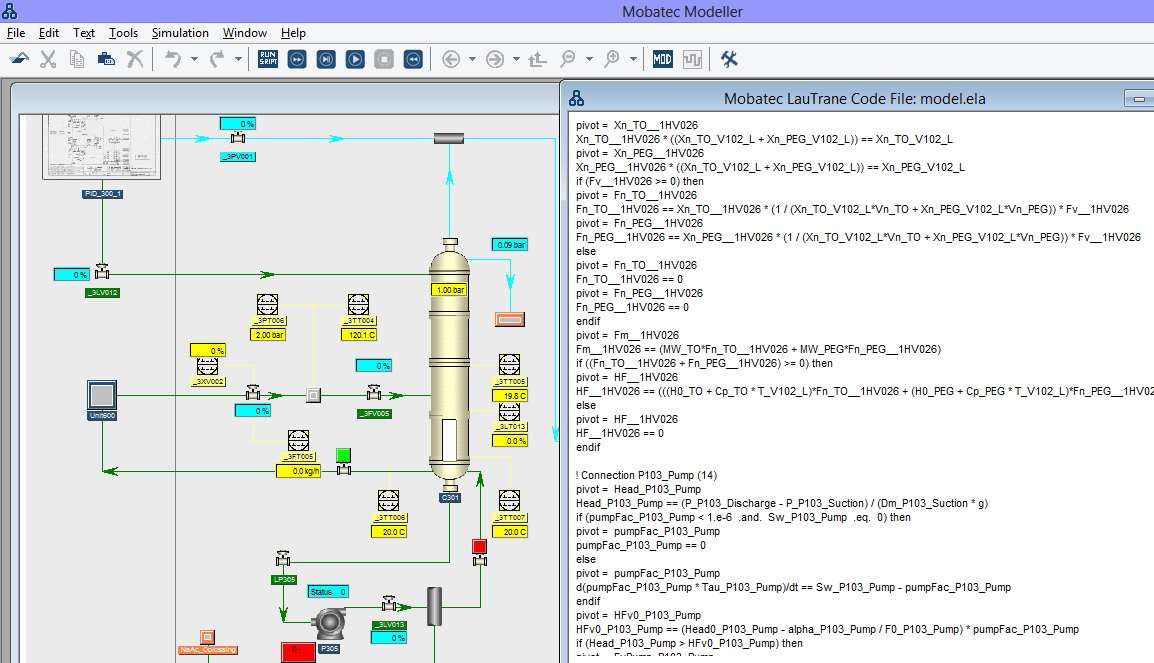

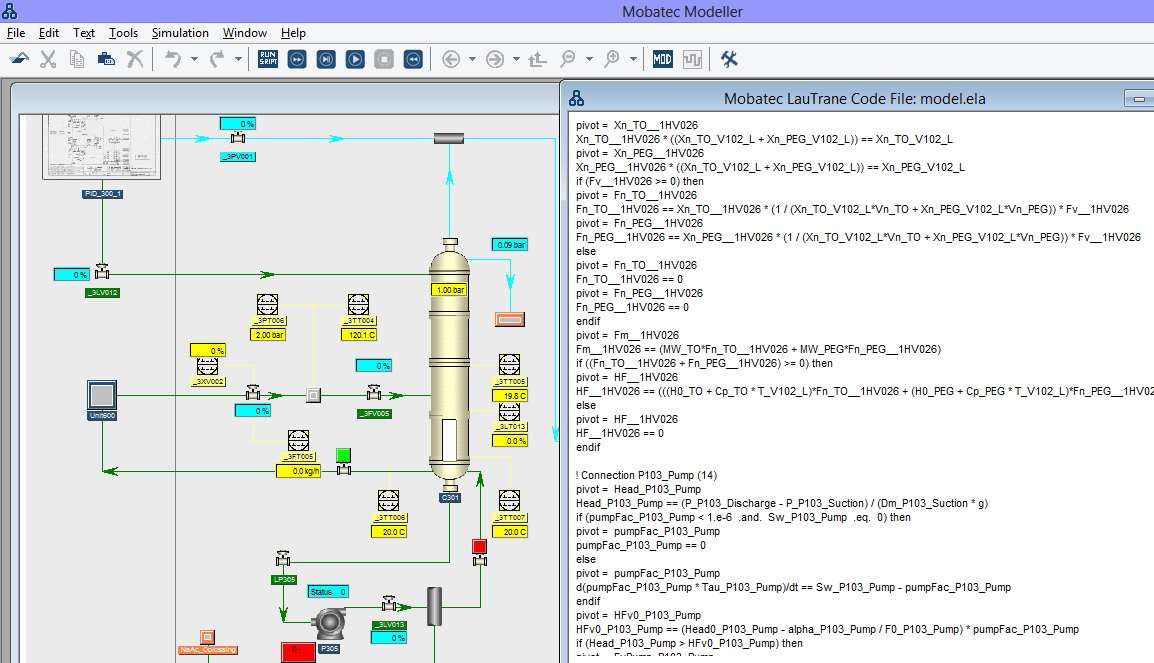

At the congress I showed people how both approaches can be visualised with Mobatec Modeller (see picture below).

On the left side you see a “flowsheet” with columns, pumps, indicators, transmitters, etc. And on the right you see a small part of the (very long) listing of the equations that constitute the entire model.

On the left side you see a “flowsheet” with columns, pumps, indicators, transmitters, etc. And on the right you see a small part of the (very long) listing of the equations that constitute the entire model.

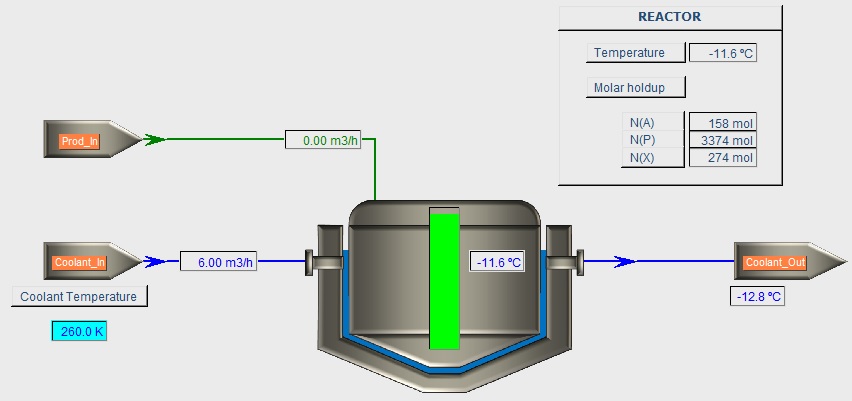

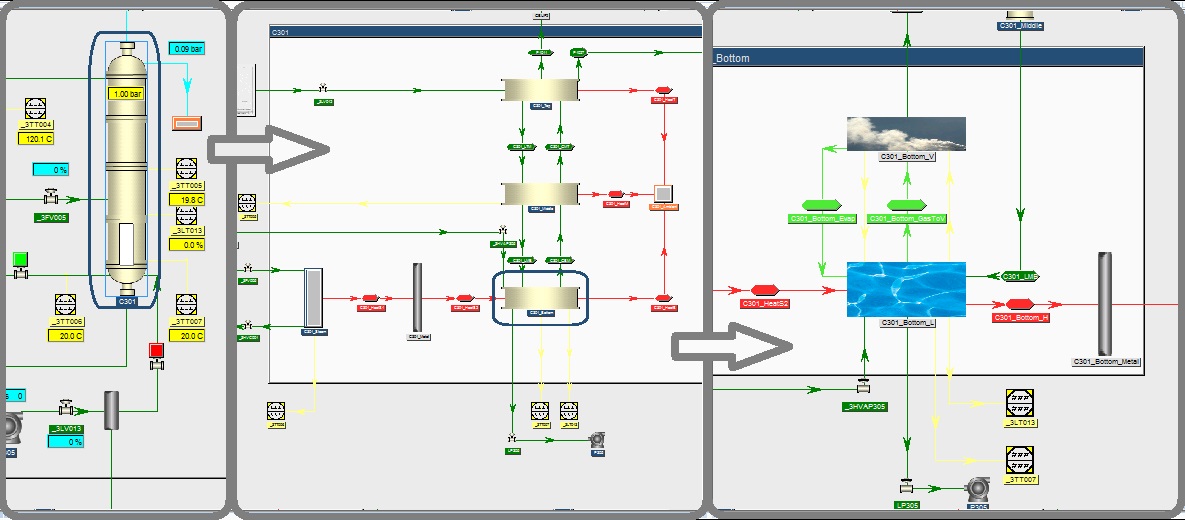

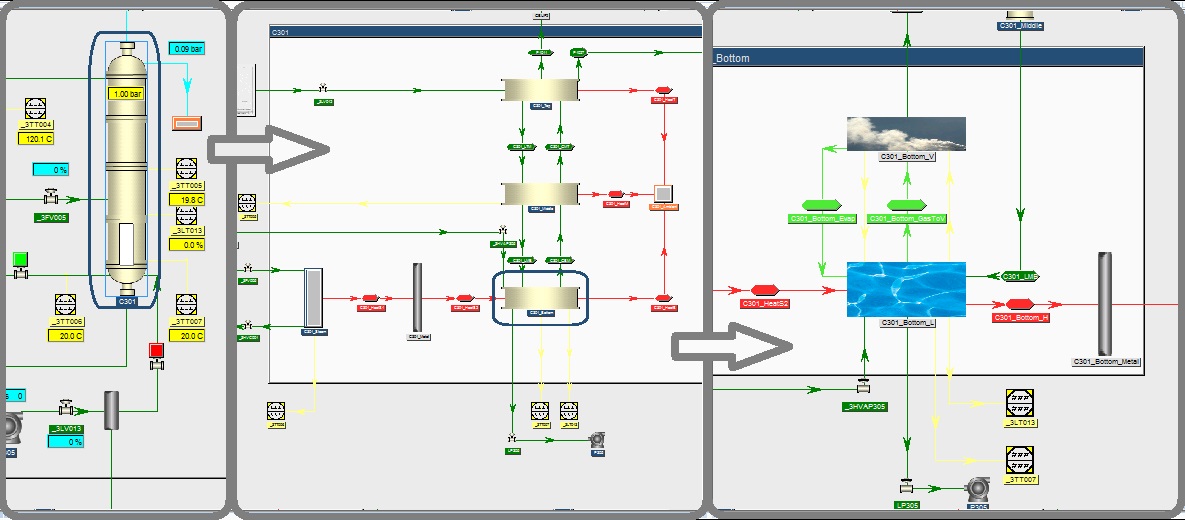

In the next screenshot you can see how you can “look inside” any part of a model with Mobatec Modeller and “zoom in” to the details of, for example, a column. This specific column was defined as a column with a fixed 3 stages. Zooming in further to the bottom stage, you notice that it consists of a liquid phase system, a vapour phase system and a “metal” system. Also several mass (green) and heat (red) streams to and from these systems are defined.

A little bit of theory is needed at this point: The modelling methodology behind Mobatec Modeller assumes that any process can be broken down into systems and connections. Systems represent a capacity, able to store mass and energy. Connections represent the transfer of mass and energy between the defined systems.

A little bit of theory is needed at this point: The modelling methodology behind Mobatec Modeller assumes that any process can be broken down into systems and connections. Systems represent a capacity, able to store mass and energy. Connections represent the transfer of mass and energy between the defined systems.

Simply “drawing” all the systems and their interconnecting connections is enough for Mobatec Modeller to automatically setup the mass and energy balances. This is a very big advantage for the user, since he cannot make any mistakes in this important part of any model definition. It’s very easy to add, reconnect, remove or copy connections (or any larger part of the model). This only affects the automatically generated part of the model.

Another big advantage of the used approach is that the debugging of the involved equations of any (part of a) model needs to be done only on “object level”, so on the level of each system and connection. Typically, the number of equations that are associated with one system or connection is not more than 10. Above all, the tool will help you with the correct equation setup and sorting, and will notify about any object that has not yet been properly setup, such that you will be assured to have a structurally solvable model.

I presented only a few differences between other tools and Mobatec Modeller for now. In the next blog post(s) I will list several more distinguishing features of Mobatec Modeller and I will elaborate on each one, such you can understand the benefit of each of them.

Mobatec strives to make process modelling easier and more accessible to a larger group of people. If you agree or disagree with our mission and/or methodology, please post your comments, insights and/or suggestions in the comment box below, such that we can all learn something from it.

To your success!

Mathieu.

———————————————–

Obviously, the goal of being there was to promote our modelling methodology and tool, since “it is Mobatecs goal to bring this easy to grasp modelling methodology to the world and to teach engineers that modelling can actually be quite easy and very valuable.”

A question I had to answer quite often during our days at the congress was: “I know about this other tool (e.g. Aspen, Hysys, gProms, Matlab, ChemCad, ProSim, etc.). How is your tool different from what I already know?”

I noticed that people (before speaking to us) really did not realise there even could be an alternative approach to modelling and they all were genuinely interested in learning what this new modelling approach could offer. Therefore, I decided to devote a blog to this topic.

As I mentioned in a previous blog post on maintainability of process models there are typically 2 ways of constructing process models nowadays:

The first and most used approach, the “Unit oriented” or “flow sheeting” approach, I would not refer to as modelling myself, since you are only connecting (sub)models, which were completely defined by other people. You are merely “simulating” in this case and hoping that the persons who developed the models did such a good job that you get the results you require for your specific setup, with your required accuracy and your specific goal. In the rare case that you can actually see all the equations (so not only a few ones in some, mostly incomplete documentation file) that are used to get to the simulation results, they are either inaccessible or the listing is very long and very difficult/complex. Don’t get me wrong here, by the way, these tools can be very powerful and useful. I am just referring to the lack of flexibility of these programs to be able to adapt (or even just understand) the actual equations of the used models.

In the other approach, The “Equation oriented” approach, the user has the “freedom” to program everything himself. This is very flexible, but typically also a very tedious job. Much (programming) experience and a lot of patience is required to get a model up and running. The listings usually get very long (and hard to maintain), which paradoxically actually makes the end result quite inflexible.

At the congress I showed people how both approaches can be visualised with Mobatec Modeller (see picture below).

In the next screenshot you can see how you can “look inside” any part of a model with Mobatec Modeller and “zoom in” to the details of, for example, a column. This specific column was defined as a column with a fixed 3 stages. Zooming in further to the bottom stage, you notice that it consists of a liquid phase system, a vapour phase system and a “metal” system. Also several mass (green) and heat (red) streams to and from these systems are defined.

Simply “drawing” all the systems and their interconnecting connections is enough for Mobatec Modeller to automatically setup the mass and energy balances. This is a very big advantage for the user, since he cannot make any mistakes in this important part of any model definition. It’s very easy to add, reconnect, remove or copy connections (or any larger part of the model). This only affects the automatically generated part of the model.

Another big advantage of the used approach is that the debugging of the involved equations of any (part of a) model needs to be done only on “object level”, so on the level of each system and connection. Typically, the number of equations that are associated with one system or connection is not more than 10. Above all, the tool will help you with the correct equation setup and sorting, and will notify about any object that has not yet been properly setup, such that you will be assured to have a structurally solvable model.

I presented only a few differences between other tools and Mobatec Modeller for now. In the next blog post(s) I will list several more distinguishing features of Mobatec Modeller and I will elaborate on each one, such you can understand the benefit of each of them.

Mobatec strives to make process modelling easier and more accessible to a larger group of people. If you agree or disagree with our mission and/or methodology, please post your comments, insights and/or suggestions in the comment box below, such that we can all learn something from it.

To your success!

Mathieu.

———————————————–